The Digital Revolution in Construction

The construction industry has entered a new era, where Artificial Intelligence (AI) is reshaping traditional workflows. Superintendents are no longer just managing labor and schedules—they're leading a digital transformation that optimizes materials logistics, site coordination, and overall efficiency. AI is not just about automation; it’s about making smarter, data-driven decisions that reduce delays, cut costs, and improve sustainability.

AI is bridging the gap between planning and execution, ensuring that construction projects run smoothly, with fewer disruptions and better resource management.

Let’s dive into the 15 ways AI-powered superintendents are revolutionizing construction.

1. Predictive Materials Ordering

AI-powered predictive materials ordering is transforming how construction sites manage supplies, ensuring materials arrive precisely when needed, minimizing waste, and optimizing costs.

How It Works

Using advanced algorithms and historical data, AI forecasts material requirements based on project timelines, weather conditions, and supplier lead times. This eliminates guesswork and prevents costly delays.

By anticipating material needs in advance, AI prevents overordering, reducing surplus materials that often end up as waste. This not only cuts costs but also supports sustainable construction practices.

Optimizing the Supply Chain

With predictive ordering, construction managers can negotiate better terms with suppliers, streamline logistics, and reduce emergency material purchases that drive up costs. AI-powered insights ensure that the right amount of materials is ordered, improving overall efficiency.

Impact on Construction Timelines

Missed deliveries and last-minute supply shortages can derail project schedules. AI minimizes these risks by aligning orders with actual project progress, ensuring smooth workflows and uninterrupted construction.

Predictive materials ordering is just one way AI is reshaping construction site management, leading to smarter, more cost-effective, and environmentally responsible building processes.

2. Real-Time Inventory Management

Managing construction materials efficiently is crucial to avoiding delays, cost overruns, and waste. Real-time inventory management powered by AI and IoT (Internet of Things) ensures that every item is accounted for, reducing downtime and improving project efficiency.

How It Works

AI-driven inventory systems track materials in real time using RFID tags, GPS sensors, and cloud-based software. These technologies provide instant visibility into stock levels, preventing shortages and overstocking.

With real-time tracking, construction managers can monitor inventory across multiple sites, ensuring materials are available where and when they’re needed.

Preventing Delays & Reducing Waste

By continuously updating inventory data, AI can send alerts when materials run low, automatically reorder supplies, and even suggest alternative sources if suppliers face delays. This minimizes disruptions and keeps projects on schedule.

Cost Savings & Efficiency Boost

Manual inventory tracking is prone to errors, leading to misplaced materials and unnecessary purchases. AI eliminates these inefficiencies, reducing material waste and optimizing cash flow by ensuring just-in-time ordering.

With real-time inventory management, construction companies gain complete control over their materials, making every project more predictable, cost-effective, and environmentally friendly.

3. Smart Route Planning for Material Delivery

Getting construction materials to the site on time is just as important as having the right inventory. Smart route planning, powered by AI and real-time data, ensures that deliveries are made efficiently, reducing costs, delays, and environmental impact.

AI in Action: How Smart Routing Works

AI-driven logistics platforms analyze traffic patterns, weather conditions, and site accessibility to determine the best routes for material delivery. These systems continuously adapt, avoiding congested roads, construction zones, and unexpected delays.

By optimizing delivery routes, companies can reduce fuel consumption, lower transportation costs, and ensure materials arrive exactly when needed.

No More Waiting: Beating Delays with Smarter Logistics

Late deliveries can throw off entire project timelines. Smart routing solutions integrate with inventory management systems to schedule deliveries precisely, ensuring materials arrive just in time without causing storage issues on-site.

Fewer Miles, Bigger Savings

Optimized routes mean fewer miles driven, leading to reduced fuel costs and lower carbon emissions. This not only benefits the bottom line but also helps construction firms meet sustainability goals.

With smart route planning, construction projects become more predictable, efficient, and environmentally responsible—making sure materials get where they need to be, exactly when they’re needed.

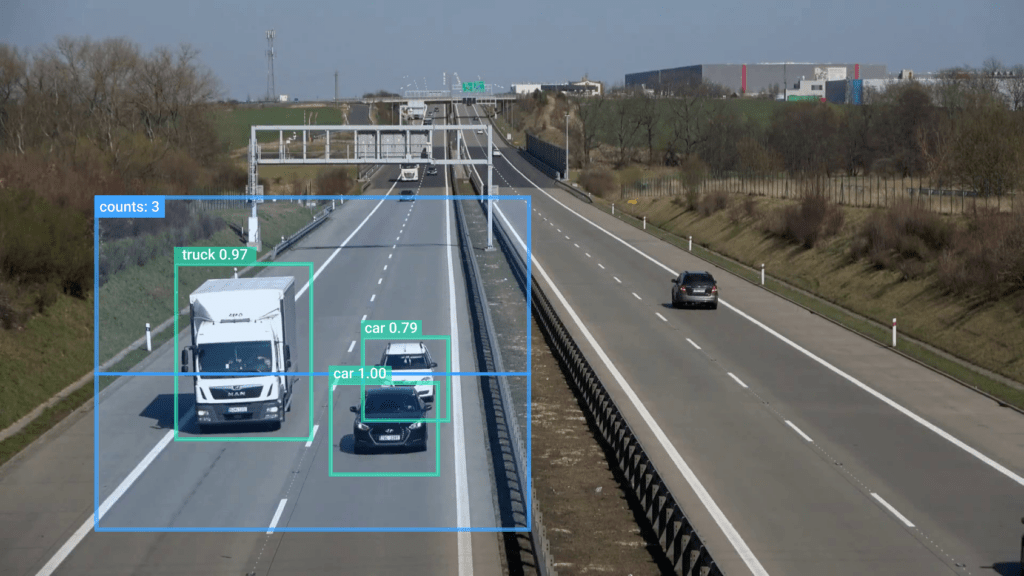

4. Traffic Flow Optimization on Job Sites

A chaotic job site slows down work, increases risks, and leads to costly delays. Optimizing traffic flow ensures that workers, vehicles, and materials move efficiently, keeping the project on schedule and improving overall safety.

AI-Powered Traffic Management: No More Gridlock

Construction sites are dynamic environments with constant movement. AI-driven traffic management systems analyze vehicle and worker movement patterns, identifying bottlenecks and suggesting the best routes for equipment and deliveries.

By implementing smart traffic flow solutions, construction sites can reduce downtime, prevent accidents, and improve operational efficiency.

Strategic Staging: Keeping Materials and Equipment Accessible

Proper material staging prevents unnecessary congestion. Smart planning tools ensure that supplies are placed in optimal locations, reducing the need for excessive transport across the site and minimizing interference with active work areas.

Digital Twins: Simulating the Best Flow

Some companies use digital twin technology—virtual models of job sites—to test different layouts and traffic patterns before making physical changes. This helps predict and solve congestion issues before they arise.

Faster Work, Safer Sites

Efficient traffic flow means less waiting, smoother coordination, and a safer work environment. With AI-driven insights and strategic staging, construction sites can operate like well-oiled machines, keeping productivity high and hazards low.

5. Inventory Forecasting for Future Needs

Running out of essential materials can stall a project, while overordering ties up capital and storage space. Smart inventory forecasting ensures that construction sites always have the right materials at the right time—without waste or delays.

AI-Driven Demand Prediction: No More Guesswork

Advanced algorithms analyze historical data, supplier trends, and project timelines to predict material requirements with high accuracy. This minimizes last-minute orders and prevents shortages.

With AI-powered forecasting, construction managers can anticipate supply needs weeks or even months in advance, reducing emergency procurement costs.

Seasonal and Market Trends: Planning for Price Fluctuations

Material costs fluctuate due to demand, supply chain disruptions, and seasonal factors. AI-based forecasting tools track market trends, allowing companies to buy materials at the right time to lock in the best prices.

Automated Reordering: Stocking Up Without Overloading

Smart inventory systems can automatically trigger restocking when supplies reach a certain threshold, ensuring a steady flow of materials without excess storage concerns.

Efficiency, Savings, and Zero Delays

By embracing predictive inventory management, construction firms can avoid supply chain surprises, streamline operations, and keep projects moving forward without costly disruptions.

6. Quality Control of Construction Materials

Ensuring top-notch materials isn’t just about compliance—it's about safety, durability, and cost-efficiency. AI-powered quality control is transforming how construction companies evaluate and approve materials before they’re used on-site.

Smart Inspections: Detecting Flaws Before They Become Failures

With the help of AI and IoT-enabled sensors, materials like concrete, steel, and timber undergo real-time analysis. These technologies identify cracks, inconsistencies, and weak points before they can compromise structural integrity.

By integrating automated defect detection, construction firms can prevent costly material failures and safety hazards.

Automated Compliance Verification: Staying Ahead of Regulations

AI-driven systems instantly compare material samples to industry standards and regulatory requirements, ensuring every shipment meets specifications. This reduces manual inspection errors and speeds up approval processes.

Predictive Material Performance: Enhancing Long-Term Durability

Advanced analytics not only assess current quality but also predict how materials will perform over time. Factoring in environmental conditions, stress loads, and wear patterns, AI helps in selecting materials that will stand the test of time.

Fewer Defects, Greater Savings

By implementing AI-powered quality control, construction companies can minimize waste, reduce rework, and ensure that every material used is up to par—saving time, money, and resources.

7. Environmental Impact Assessment for Sustainable Construction

Sustainability isn’t just a trend—it's the future of construction. AI-powered environmental impact assessments (EIA) are helping developers make informed decisions that minimize ecological damage while optimizing efficiency.

AI-Powered Site Analysis: Choosing the Right Location

Before construction even begins, AI evaluates land conditions, biodiversity, and potential disruptions to ecosystems. By analyzing satellite imagery, topographical data, and climate models, it helps builders select sites with minimal environmental impact.

Smart site selection reduces deforestation, prevents soil erosion, and preserves natural habitats.

Carbon Footprint Tracking: Measuring & Reducing Emissions

AI-driven tools calculate emissions from construction activities, material production, and transportation. By suggesting eco-friendly alternatives—such as low-carbon concrete or locally sourced materials—AI helps lower the project’s overall carbon footprint.

Water & Energy Efficiency: Optimizing Resource Usage

AI monitors water and energy consumption throughout the construction process. It recommends conservation strategies, such as rainwater harvesting systems or energy-efficient equipment, to minimize waste and reduce operational costs.

Waste Management: Cutting Down on Construction Debris

Machine learning models predict material needs with precision, preventing over-ordering and reducing excess waste. AI can also sort and classify demolition debris, improving recycling rates and landfill diversion.

Long-Term Environmental Impact Predictions

AI doesn’t just assess short-term effects—it forecasts how buildings will interact with their surroundings over decades. By analyzing factors like urban heat islands, flood risks, and air quality, AI helps create structures that are resilient and sustainable.

With AI-driven environmental assessments, construction companies can balance growth with responsibility—ensuring that today’s projects don’t come at tomorrow’s expense.

8. Supplier Performance Analysis for Optimal Collaboration

Reliable suppliers are the backbone of any successful construction project. AI-driven supplier performance analysis helps companies make data-driven decisions, ensuring materials arrive on time, within budget, and at the highest quality.

Tracking Supplier Reliability: Data-Driven Insights

AI compiles historical data on delivery times, material quality, and order accuracy. By analyzing patterns, it identifies which suppliers consistently meet deadlines and which ones cause delays. <blockquote> Consistent, reliable suppliers reduce downtime and prevent costly project overruns. </blockquote>

Quality Assurance: Ensuring Top-Tier Materials

By integrating real-time quality control data with supplier records, AI detects trends in material performance. If a particular supplier’s materials show defects over time, AI flags potential risks before they impact the project.

Cost Efficiency: Finding the Best Deals Without Sacrificing Quality

AI algorithms compare pricing trends across multiple suppliers while considering factors like bulk discounts, shipping costs, and market fluctuations. This allows contractors to secure the best deals without compromising quality.

Proactive Risk Management: Preventing Supply Chain Disruptions

AI can predict potential disruptions—whether from geopolitical events, weather conditions, or market shortages. It provides alternative supplier recommendations and suggests contingency plans to keep projects running smoothly.

Optimizing Supplier Collaboration for Long-Term Success

Instead of just evaluating past performance, AI fosters better supplier relationships by suggesting improvements in communication, logistics, and contract terms. This proactive approach leads to stronger, more efficient partnerships.

With AI-powered supplier analysis, construction firms can build smarter, faster, and with fewer supply chain headaches.

9. Crew Scheduling Optimization for Efficient Workflow

Managing a construction crew is like conducting an orchestra—every worker needs to be in the right place at the right time. AI-driven crew scheduling ensures an optimized workflow, reducing downtime and keeping projects on track.

Workforce Allocation: The Right People, The Right Time

AI analyzes project timelines, worker availability, and skill sets to assign tasks efficiently. This minimizes idle time and ensures that specialized workers are deployed only when needed.

Optimized scheduling prevents bottlenecks and ensures smooth project execution.

Real-Time Adjustments for Unforeseen Changes

Construction sites are unpredictable. Weather delays, material shortages, or last-minute design changes can disrupt schedules. AI-powered tools adapt in real time, reallocating workers and adjusting timelines to prevent costly downtime.

Boosting Productivity with Predictive Analytics

By studying past project data, AI can predict workforce needs for future phases, helping managers avoid labor shortages or overstaffing. This ensures efficiency without unnecessary payroll expenses.

Balancing Workloads to Prevent Fatigue

Overworked crews lead to mistakes, safety risks, and burnout. AI systems balance workloads, ensuring fair shifts and proper rest periods while maintaining progress.

Seamless Coordination Between Teams

AI-driven scheduling integrates with project management platforms, keeping supervisors, workers, and subcontractors aligned. This prevents scheduling conflicts and ensures seamless collaboration across different job site teams.

With AI-powered scheduling, construction crews work smarter—not harder—leading to faster project completion and higher-quality results.

10. Comprehensive Risk Assessment for Construction Projects

Construction sites are full of potential risks, from safety hazards to financial setbacks. AI-powered risk assessment tools analyze vast amounts of data to identify, predict, and mitigate risks before they become costly problems.

Identifying Hazards Before They Happen

AI scans historical project data, weather forecasts, and real-time site conditions to flag potential risks—whether it’s material delays, safety concerns, or budget overruns. This proactive approach prevents last-minute surprises.

Anticipating risks allows construction teams to implement solutions before issues escalate.

Predictive Safety Measures for a Secure Job Site

By analyzing past incidents, AI detects patterns that could lead to future accidents. It suggests preventive measures such as additional safety training, protective gear, or workflow adjustments to minimize risks.

Financial Risk Forecasting: Staying Within Budget

Unexpected costs can derail a project. AI assesses material price fluctuations, labor costs, and potential delays to provide accurate budget forecasts, helping project managers make informed financial decisions.

Legal & Compliance Assurance

Construction regulations change frequently, and non-compliance can lead to fines or shutdowns. AI tracks regulatory updates and ensures all permits, safety protocols, and environmental guidelines are met throughout the project.

Enhanced Decision-Making Through Data Insights

Risk assessment tools integrate with project management software, providing real-time insights and actionable recommendations. This empowers teams to make smarter, data-driven decisions, reducing uncertainties and improving project outcomes.

By leveraging AI for risk assessment, construction firms can enhance safety, control budgets, and complete projects with fewer disruptions—leading to smoother operations and greater profitability.

11. Real-Time Communication for Enhanced Collaboration

Construction projects involve multiple teams, suppliers, and stakeholders, making efficient communication essential for smooth operations. AI-driven real-time communication tools streamline interactions, ensuring everyone stays informed and aligned.

Instant Updates for Faster Decision-Making

AI-powered platforms provide instant notifications on project changes, material deliveries, and schedule adjustments. This eliminates delays caused by miscommunication and keeps workflows on track.

Real-time updates mean fewer misunderstandings, faster approvals, and reduced downtime.

Smart Chatbots & Virtual Assistants

AI chatbots assist with answering queries, scheduling meetings, and providing quick access to critical project data. They help teams retrieve blueprints, safety protocols, or inventory levels without manual searches.

Speech-to-Text and Voice Commands for Hands-Free Communication

Workers on-site can use voice commands to send messages, report issues, or update progress logs. AI transcribes conversations, ensuring that verbal updates are documented and accessible to all stakeholders.

AI-Powered Language Translation for Global Teams

Large-scale projects often involve multilingual teams. AI-driven translation tools enable seamless communication across different languages, improving collaboration between international suppliers, contractors, and engineers.

Integration with Project Management Tools

AI-enhanced communication systems sync with construction management software, allowing for real-time tracking of tasks, resource allocation, and issue resolution—all from a single platform.

By leveraging AI for real-time communication, construction teams can work more efficiently, reduce errors, and keep projects running smoothly, ultimately improving productivity and project success rates.

12. Cost Control Through AI-Driven Analysis

Keeping construction projects within budget is a constant challenge. AI-powered cost control solutions analyze financial data, identify inefficiencies, and provide insights to optimize spending.

Predictive Budgeting for Accurate Estimates

AI examines past projects, market trends, and real-time cost fluctuations to generate precise budget forecasts. This helps teams anticipate expenses and allocate funds efficiently. <blockquote> AI-driven budgeting reduces the risk of cost overruns by identifying potential financial pitfalls early. </blockquote>

Automated Expense Tracking & Fraud Detection

AI monitors transactions, invoices, and labor costs in real time, flagging discrepancies or unusual spending patterns. This prevents budget leaks and ensures financial transparency.

Material Cost Optimization

By analyzing supplier data and market trends, AI suggests the best times to purchase materials, securing lower prices and minimizing waste. It can also recommend alternative materials with similar properties but better cost efficiency.

Labor Cost Efficiency & Workforce Planning

AI assesses worker productivity, overtime trends, and scheduling efficiency to optimize labor costs. By predicting workload fluctuations, it helps managers prevent understaffing or excessive overtime expenses.

Scenario Analysis for Financial Risk Mitigation

AI can simulate different financial scenarios based on project changes, economic shifts, or unforeseen disruptions. This allows teams to adjust budgets proactively and prepare contingency plans.

By leveraging AI for cost control, construction firms can maximize profitability, reduce financial risks, and ensure smarter spending throughout the project lifecycle.

13. Compliance Monitoring for Regulatory Adherence

Regulatory adherence is a critical aspect of any construction project, ensuring safety, environmental responsibility, and legal compliance. AI-driven compliance monitoring streamlines this process, reducing risks and costly penalties.

Automated Permit & Regulation Tracking

AI systems continuously update and cross-check project requirements against local, state, and federal regulations, ensuring all necessary permits and documentation are in place.

Missing a permit or failing to meet a regulation can lead to severe delays and fines—AI helps avoid these pitfalls.

Real-Time Site Inspections & Safety Audits

AI-powered cameras and IoT sensors monitor construction sites, detecting non-compliance with safety standards, such as missing PPE, improper scaffolding, or hazardous material handling.

Digital Documentation & Reporting

AI organizes and verifies compliance documents, automatically generating reports for inspectors and project managers. This minimizes paperwork errors and simplifies audits.

Predictive Risk Assessment for Legal Compliance

By analyzing historical data and ongoing project activities, AI predicts potential compliance risks before they escalate, helping teams take corrective actions early.

Environmental & Sustainability Compliance

AI tracks emissions, waste disposal, and resource usage to ensure adherence to green building standards, reducing environmental impact and enhancing sustainability certifications.

With AI-driven compliance monitoring, construction firms can proactively maintain regulatory adherence, improve workplace safety, and avoid costly legal issues.

14. Data-Driven Decision-Making for Optimal Construction Outcomes

In today’s fast-paced construction industry, making informed decisions is key to efficiency, cost savings, and project success. AI-driven data analytics empowers construction teams with real-time insights, predictive modeling, and smarter resource allocation.

Real-Time Data Collection & Analysis

AI gathers data from various sources—IoT sensors, drones, site cameras, and project management software—to provide instant updates on project progress, material usage, and labor productivity.

Instead of relying on guesswork, project managers get clear, data-backed insights for better planning and execution.

Predictive Analytics for Risk Management

By analyzing past projects and current site conditions, AI predicts potential delays, safety hazards, and budget overruns, allowing proactive problem-solving before issues arise.

Optimized Resource Allocation

AI-powered tools assess workforce efficiency, equipment usage, and supply chain logistics to minimize waste and improve resource distribution across multiple job sites.

Enhanced Budget & Cost Control

AI algorithms track expenses in real time, comparing them to projected budgets and flagging anomalies, helping companies stay on track financially.

Improving Design & Planning Accuracy

With AI simulations and Building Information Modeling (BIM) integrations, construction teams can visualize projects, optimize layouts, and test structural integrity before breaking ground.

Data-driven decision-making transforms the construction process, ensuring projects are completed on time, within budget, and with maximum efficiency.

15. Embracing Continuous Improvement in Construction Management

The construction industry is evolving rapidly, and companies that prioritize continuous improvement stay ahead of the competition. By leveraging AI, data analytics, and process optimization, firms can refine workflows, boost efficiency, and ensure long-term success.

Leveraging AI for Process Optimization

AI analyzes project performance data, identifying inefficiencies and recommending improvements. From scheduling adjustments to smarter material usage, continuous optimization leads to better results over time.

Implementing Feedback Loops for Ongoing Refinement

Regular feedback from workers, project managers, and AI-driven analytics helps refine strategies. By tracking performance metrics, teams can identify what works and make real-time adjustments.

A culture of continuous learning ensures that every completed project contributes to smarter, more efficient future builds.

Enhancing Training & Workforce Development

AI-powered training modules and on-site augmented reality simulations allow workers to upskill efficiently, improving safety and productivity.

Standardizing Best Practices with AI Insights

AI compares past and current projects to highlight best practices, helping teams create standardized procedures that improve overall efficiency.

Automating Routine Tasks for Greater Efficiency

From document management to predictive maintenance, automation reduces manual workloads, freeing up skilled professionals for higher-value tasks.

By embracing continuous improvement in construction management, companies foster innovation, enhance productivity, and deliver better projects with each build.

AI: A Catalyst for Construction Transformation

The future of construction lies in data-driven decision-making and AI-powered optimization. By embracing AI, superintendents are not just improving efficiency—they're reshaping the entire industry for a more sustainable, cost-effective, and technologically advanced future.